Harmonic waves can travel thru the drive

train and thru the crank. If there is nothing at the end

of the crank to absorb the wave, it will travel back in

the opposite direction to meet the next wave. This causes

the unfavorable harmonic vibration. The first thing to take

the abuse is the oil pump gear and you know what happens

when that breaks. ALSO, pulling weight off of the crank

that close to the center line will add ZERO horsepower or

rpm capability. Don't fool yourself on this. Think of how

big and thick the counter weights are on a crankshaft. The

harmonic balancer is just another externally added counterweight

that happens to absorb negative wave energy. Honda engineers

were not stupid or naive. Don't try to out think them in

this case, use a harmonic balancer.

Personal experience...We

abuse the drive train launching at 8000 rpm and shifting

over 10,000 rpm. The aluminum under the flywheel bolts started

to eat away and the flywheel started to vibrate back and

forth. When it came completely loose it sent a shock thru

the crank so strong that it snapped the key holding the

harmonic balancer in place. The balancer spun on the crank,

put the crank fired ignition out of time and shut the motor

off. When pulling everything apart, we found that the shock

wave had actually also bent the crank to the point where

it was unusable again. This proved to me the useful purpose

of a harmonic balancer. We run steel flywheels now, BTW.

UPDATE:

Since writing this, we have started selling the ATI line

of dampers for the following reasons..

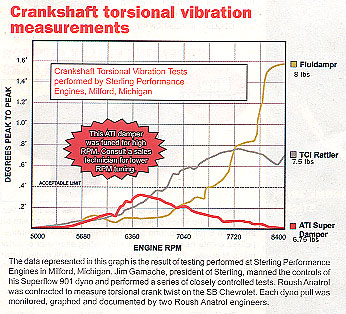

1)The ATI damper continues to dampen vibrations

to unlimited rpms whereas the fluid unit loses its effectiveness

at about 7000 rpm. Check the graph below.

2)The

ATI is 1.25 pounds lighter than the fluid unit.

3)The ATI is rebuildable.

4)Viscous fluid dampers are sealed. The

inertia weight can become locked by bearing failure or,

more commonly, from the silicone turning to a solid mass.

Your first warning of damper failure will probably be a

broken crankshaft resulting in the replacement of your damper

and the engine.

5)ATI units are used on all NASCAR engines

as they were designed specifically for high performance

engines. Their design is fail safe, efficient and available

for any engine application. They are SFI certified.

6)Bolt on crank trigger wheels available

with the ATI.

7)ATI was able to build a custom damper

for our race car. It is for a S2000 engine with a Chevy

bolt pattern to help us connect our dry sump pump to our

engine.

8)Much more detailed information here.