|

$850

Shipped

PLEASE CALL FOR APPLICATIONS

• Designed & Manufactured

in the USA

• Built With High Strength 9310 Alloy Steel

• Exclusively Made, High Strength Fasteners By

ARP®

• Enhanced No-Load Bias Ratio

• Interchangeable Friction Plates

• Limited LIFETIME Warranty

| Application |

| GSR B18C |

| B16 LS |

| K20/24 RSX/TSX |

| H22 Prelude |

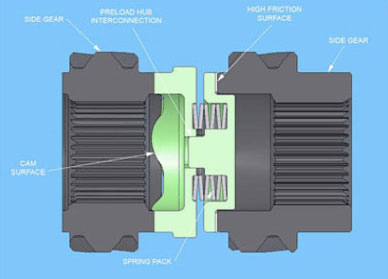

Enhanced No-Load Bias Ratio via Wave Design Center Pack

One of the known shortcomings of a typical torque biasing

differential is its loss of drive (behaving much like

an open diff) under zero or near-zero torque conditions

(for example, when there is 'no-load' applied through

the drivetrain, either at vehicle stationary and/or

transition from engine driving vehicle to engine braking

and back).

The Wavetrac® differential uses a patent pending

design to improve grip in low traction conditions. Precisely

engineered, converging / diverging wave profiles are

placed on one side gear and its mating preload hub.

As the two side gears rotate relative to each other,

each wave surface climbs the other, causing them to

move apart. This imparts an increased normal force through

the side gears, increasing the bias ratio as a function

of load. This increase occurs automatically only when

conditions find it necessary, and it 'reverts' back

to its nominal bias ratio quickly and seamlessly, maintaining

optimal drivability and performance at all times. It's

like having two differentials in one: you get the benefit

of a higher bias ratio when needed without detriment

to the car's handling.

Interchangeable

Friction Plates Provide Controlled Bias

Here's something else you won't find in any other design:The

Wavetrac® differentials behavior can be altered

in the field to suit your needs. It comes standard with

carbon-fiber bias plates for the best all around performance.

Interchangeable plates using materials with different

friction coefficients to fine-tune the bias ratio are

sold separately.

These friction plates provide a mechanism to tune the

response of the differential as a function of applied

torque load. The applied torque load manifests itself

as an axial load from the differential pinions into

the housing. This axial force is then considered a normal

force into the friction plate, and as a function of

the effective coefficient of friction, will provide

a resistive torque to the rotational motion of the differential

pinions. The resistive torque will add to the resistance

of relative rotation of all components within the differential.

The resistive force, however, is non-uniform since it

is a function of the axial load from the differential

pinions. The unbalance of the resistive torque will

manifest as non-uniform energy absorption within the

differential causing a bias ratio.

Superior Design, Materials, and Construction

Designed from a clean sheet, the new Wavetrac® Differential

brings current gear technology to the market. Internally,

its gear tooth forms are optimized for strength and

improved oil film retention over competitive designs.

Our gear package is smaller, reducing overall mass,

yet is more durable. Attention was also paid to the

side gear/axle interface, putting as much material thickness

as possible in this critical area - most important when

power levels get high.

Each Wavetrac® Differential is crafted from the

highest quality materials available. The internal gears

are made from high strength 9310 alloy steel. The diff

bodies are machined from case hardened steel billet.

To complete the package, every Wavetrac® differential

is built using high quality, high strength fasteners

exclusively from ARP®, the world leader in fastener

technology.

|